Tag: mirror

Postcard from the Summit – Mirror in the Hall

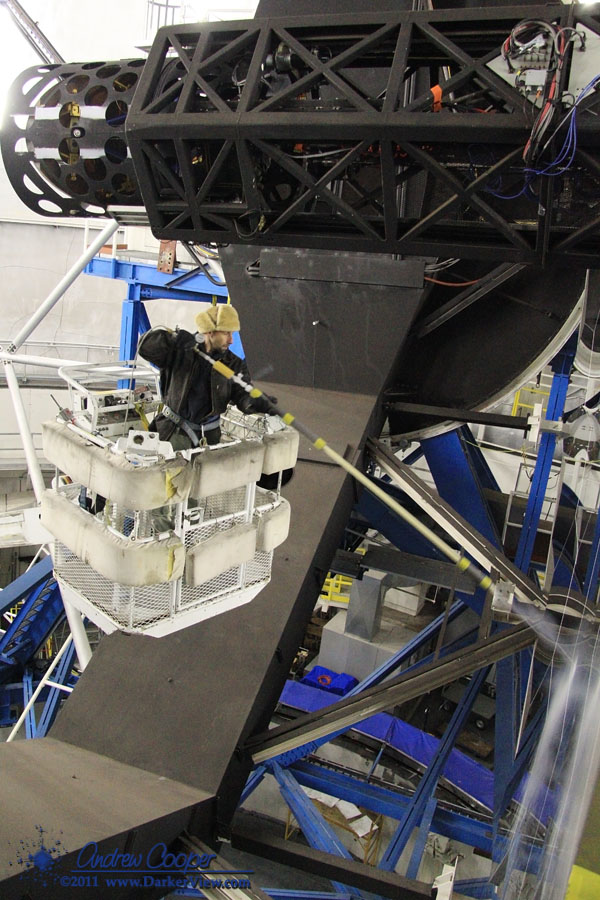

The radio call goes out… “Mirror in the hall, mirror in the hall!” Everyone gets out of the way as a mirror segment is rolled down the central hallway. It is being moved to the coating facility where it will be cleaned, stripped and re-coated with a layer of fresh aluminum.

Polishing an 8m Mirror

My friend Dean Ketelsen has posted another great bit of video from the Steward Mirror Lab where he works. This time it is time lapse of polishing one of the eight meter GMT mirrors.

Somehow the video does not do justice to the sheer size of an eight meter mirror, it looks smaller than it really is. Be sure to read his description for all of the technical details.

Shiny

A telescope relies on the quality of the primary mirror. The shape must be exquisite perfection, with errors measured in millionths of a meter. The reflective coating must also perform to high standards, reflecting well over 90% of the light across a wide region of the spectrum.

Keck uses pure aluminum to coat the surface of each mirror segment, chosen for its excellent reflectivity in the visible and infrared parts of the spectrum. It takes only 20.5 grams of aluminum to coat an entire Keck primary mirror. This thin layer of aluminum degrades with time, losing several percent of it’s reflectivity each year. Eventually it must be replaced.

Re-coating a mirror is a painstaking process of stripping the old coating, carefully cleaning the mirror, the placing the mirror in a vacuum chamber to deposit a new metal coating onto the glass. The process takes about a week per segment, with one full time technician dedicated to the task, with a little help to handle some of the more intense parts of the process.

An advantage of a segmented telescope is that individual segments may be swapped in a single day. Telescopes utilizing monolithic mirrors must shut down for weeks to remove the primary mirror, strip clean and re-coat. With spare segments available the maintenance crew can perform the task of re-coating on a reasonable schedule, without taking the telescope off sky for an extended period.

At Keck there is a special storage facility for segments awaiting re-coating and those that are ready for installation back into the telescope. The process is continuous, once the last segment is finished, it is time to start the rotation again.

Once cleaned the mirror is moves to a large vacuum chamber where the new coating will be deposited. Here the mirror is positioned face downwards. With the cover reinstalled on the chamber it will take most of a day to pump out the air and ready the chamber for coating.

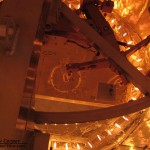

Glow discharge is a method of cleaning a surface prior to vacuum coating it. A high electrical charge is placed on an electrode just below the mirror in a partial vacuum. The result is something like creating a storm of electrons to blow any remaining impurities off the surface of the mirror. It is also a very beautiful process, looking through the ports one can see a brilliant violet haze around the electrode with sparks flickering along it’s length.

The coating process takes only a few minutes once the electrodes are turned on. Peering in through the small view port a cheery red glow is seen from each of the electrodes at the bottom of the chamber. The view only lasts a few moments as the cloud of vaporized aluminum soon reaches the view port and the glow fades as the window is covered by a layer of deposited aluminum along with the mirror segment.

What emerges from the chamber is a mirror with a beautiful, reflective metal coating. A few tests will be performed to insure the coating meets specification. If all is well the mirror segment will be prepared for installation in the telescope. It will await another segment exchange when it will replace another segment that has become dull with years of exposure to the elements. That segment will then receive it’s turn in the coating chamber.

A Few Grams of Aluminum

It is an observation I have made before, but one that continually amazes me… Each Keck telescope consists of three hundred tons of steel and glass, with one simple purpose, to hold a few grams of aluminum in the perfect shape necessary to collect the light from distant stars and galaxies.

The layer is just thick enough to reflect nearly all of the light, any thinner and too much light would penetrate the mirror, any thicker and small variations in the coating would begin to distort the shape of the mirror.

How much aluminum?

Density of Al…

2.70g/cm³

Area of a Keck Primary…

36 x 2.598 x (0.9m)² = 75.75m²

Mass of Al…

2.70g/cm³ x 75.75m² x 100nm x 1,000,000cm³/m³ = 20.45g

20.45g = 0.71oz (if you prefer imperial)

Just how much aluminum is really on each Keck primary mirror? Simple enough to calculate… just multiply the surface area of thirty six hexagons by the thickness of the aluminum layer to figure the total mass of metal used.

The figures are found in the sidebar, and the answer is surprisingly little, about 20.5g. In comparison, an empty 12oz soda can weighs about 15g, thus it take a bit more than one soda can of aluminum to cover the Keck’s 10 meter primary mirror.

There is much more to a telescope than just one simple layer of aluminum. But that one component is critical. It is the mirror that gets a great deal of the attention. The primary mirror is what gives a large observatory the ability to capture light from the earliest eras of the universe, billions of years in the past.