Condensation

To reduce dark current and noise it is necessary to cool a CCD well below ambient temperature. But as anyone who had sipped a cold soda knows, a cold surface will cause moisture to condense out of the air. Moisture can damage the CCD, but when cooling below zero the moisture turns to frost. Frost can quickly destroy a CCD by damaging the surface structure or even breaking the bond wires. Even worse is the effect of frost on a micro lens CCD. To prevent this the CCD chip is placed in a chamber with the moisture removed by some method.

The Effect

Frost or condensation can form almost unnoticed, just a faint fogging of the image that would fool the observer into thinking a cloud drifted through or the focus is slightly off. Often it cannot be seen in a flat as it just serves to further diffuse the light. Operators should be aware that if odd fogging of the image occurs, often across only part of the image, that the system should immediatelyturned off and allowed to warm. If possible examine the CCD as quickly as possible to confirm the presence of condensationor frost.

Prevention

The best solution is to completely remove the air by creating a vacuum. This also allows the CCD to get colder as there is no air to conduct or convect heat to the chip. The problem with a vacuum is that it requires a much heavier chamber and window. Another issue is that air and moisture will eventually leak through the seals, however good they are. Thus a vacuum chamber will have to be serviced with a vacuum pump on a regular basis using a process known as 'pump and bake'. This is done by connecting the chamber to a high quality vacuum pump while warming the chamber to drive off moisture and any other contaminants. This should be done every six months to a few years depending on the quality and type of the seals used.

The next best solution is to replace the air with dry nitrogen. With this solution there is no moisture in the chamber, since there is no pressure difference across the seals moisture takes much longer to leak into the chamber. Combined with a desiccant compound in the chamber to absorb what moisture does leak in, this method can result in excellent performance for a long period of time, five to ten years without servicing.

The simplest solution is to use only a desiccant compound to absorb the moisture in the chamber. This works, but requires more frequent servicing as much of the desiccant's capacity is consumed by the initial drying out of the chamber. The desiccant will need to be removed and baked to drive off the moisture on a regular basis, usually annually.

Micro-Lens Frost Damage

The effects of frost can range from none to catastrophic. But when the CCD has micro-lenses the effect is usually the latter. Micro lenses are made from a relatively soft material and frost readily distorts the shape of the lens. The effect is reduce or destroy the effect of the lens so that the pixel no longer receives light properly.

The damage is permanent and the only solution is the replacement of the CCD. This is likely on basically all current generation Sony CCD's and all M-series Kodak chipthat are widely used in astro imaging.

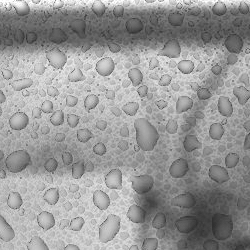

Heavy condensation on the surface of a CCD resulting from a loss of chamber integrity allowing moisture to condense on the surface of the CCD. This Sony chip also has micro-lens damage from frost, note the dark pixels between the droplets.

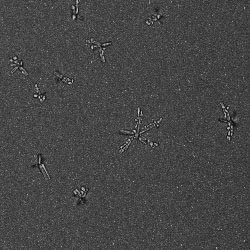

Frost damage of the micro-lenses shown in a flat, note the random dark pixels where the lens is damaged and not concentrating the light properly.

Ice crystals beginning to form with a very low CCD surface temperature and a small amount of moisture in the chamber.