There is always something broken. It is just a rule on boats. Usually is is more than one thing, you have a list. Just so long as nothing on the list is truly critical.

Still, the list does not seem to get any shorter.

Nothing really critical… Until we noticed the batteries were not charging.

Hmmm… That might be a problem.

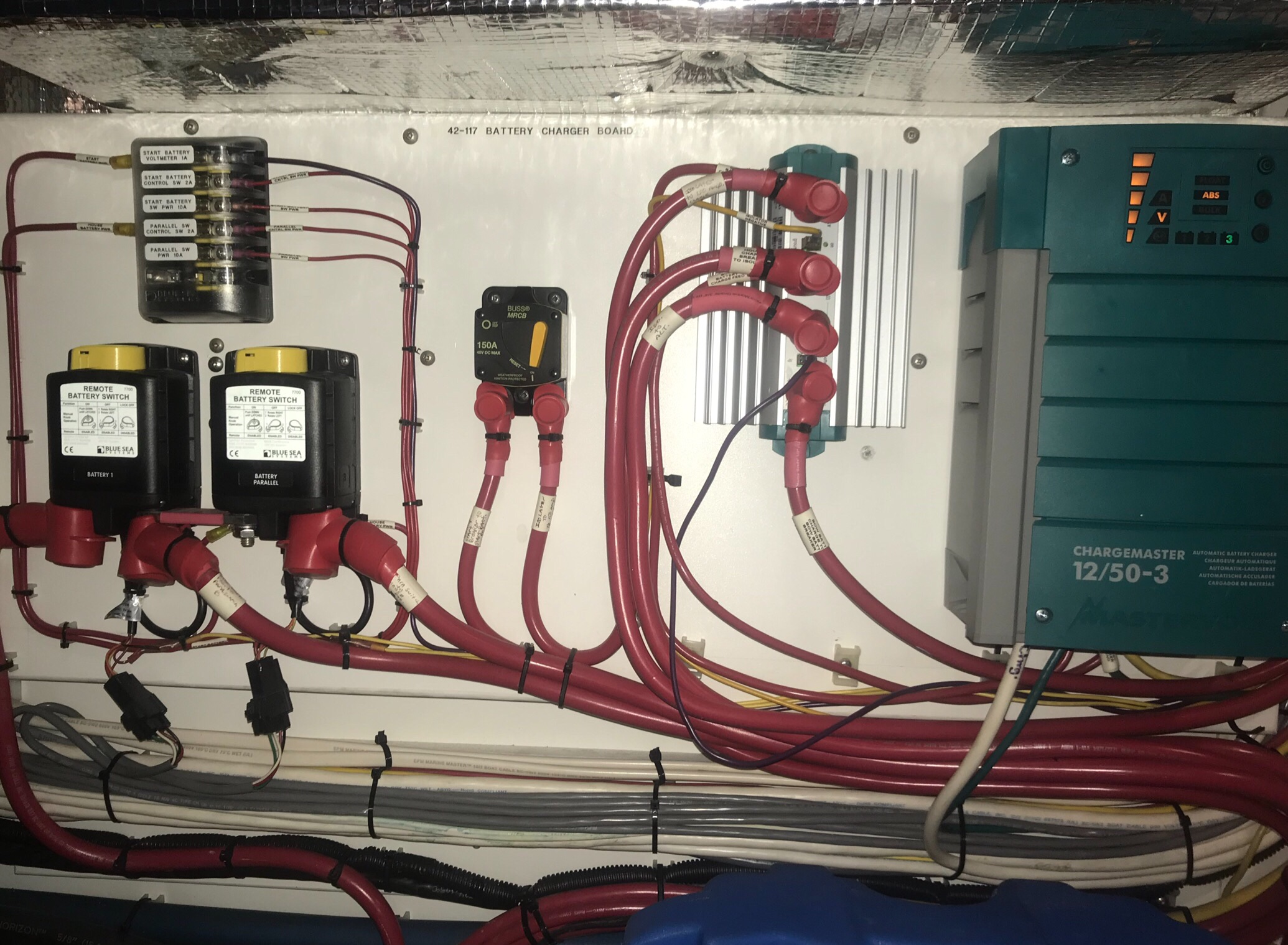

I spend a few minutes poking about in the engine room. The battery circuits are fairly simple, everything is just bolted to the forward bulkhead and fairly easy to get at. There is some complication in that we also have a battery charger that runs off AC power, that adds a few more wires, circuit breakers, and other electrical boxes to the setup.

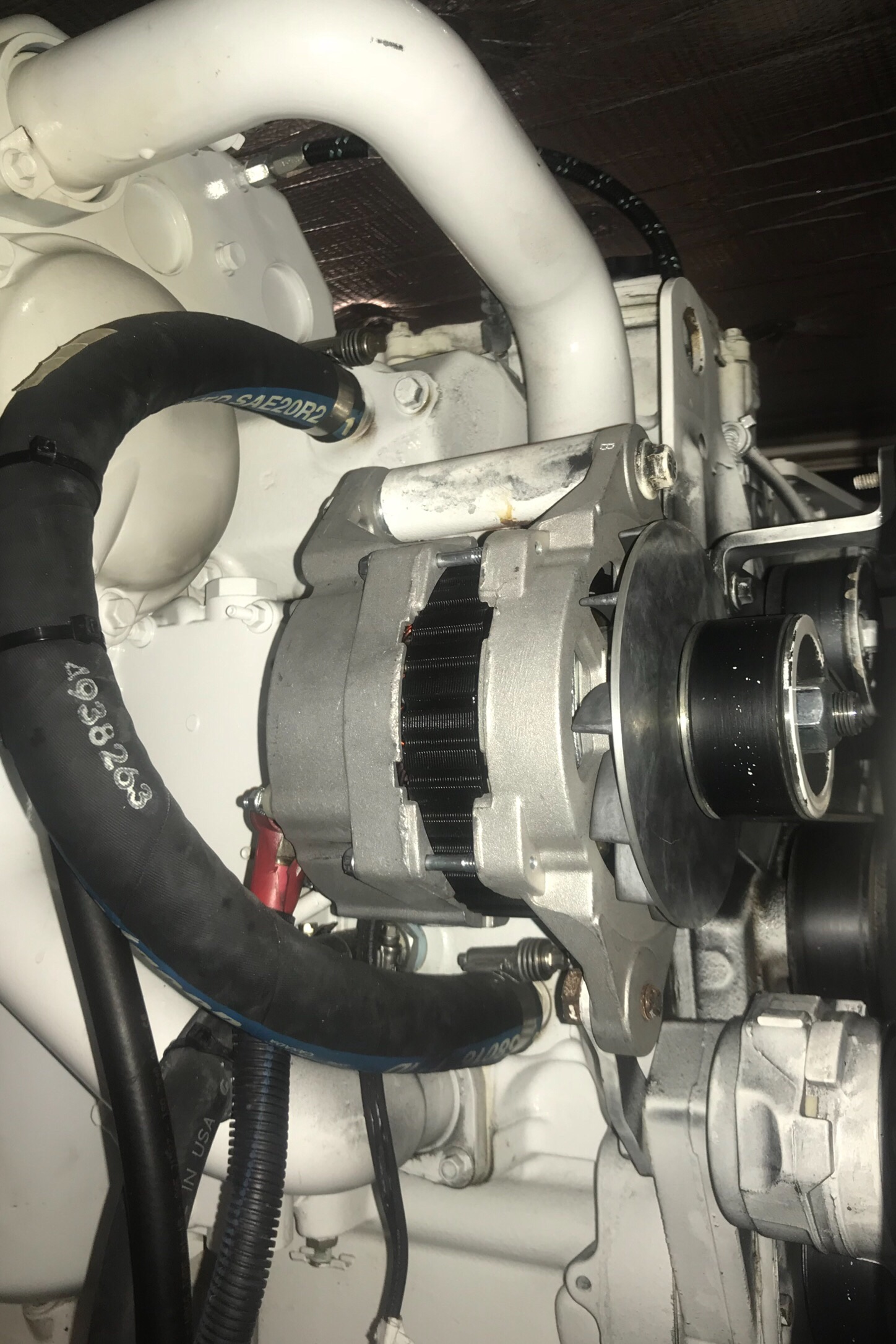

Yeah… The alternator is dead. It is putting out 2.9 volts, not 12 to 13 volts..

Hmmm… That is a problem.

Fortunately we can charge our batteries. We have to run the generator and use the battery charger. We can keep cruising, with no redundancy. Lose the gen-set or the battery charger and we will soon be dead in the water when the batteries give out.

Of course this happens in the middle of a rather large bit of wilderness, a long ways from any substantial port that would have the needed parts.

So we run the gen-set for a few hours each morning, and a few hours each evening charging the batteries. The nights are punctuated by getting up to check the battery voltages, on the panel just outside my cabin door.

Those few days of cruising allow us to get to Shearwater. This little port serves the cruisers coming up from Vancouver and transiting the Inside Passage. Shearwater offers a fairly good marine supply house and a small boatyard.

We spend the night in a very pretty little cove a few miles from Shearwater. In no hurry to run back to dock I take a couple hours to kayak around a saltwater lagoon playing tag with a family of otters. One nice result of the breakdown.

At 1:30pm the water taxi arrives from Bella-Bella with our alternator aboard. Good, this will take 20 minutes… Not.

A broken 1/2″ ratchet… Run up to the marine supply for a 1/2″ breaker bar. $20 later we can get the serpentine belt off.

We do not have a socket big enough to get the pulley off the old alternator. Run up to the boatyard where the mechanic quickly swaps the pulleys with an air ratchet. We slide him enough loonies for a round of beer.

Done. The batteries are now charging! We head south towards Queen Charlotte and a open ocean crossing with all systems good to go. Everything critical at least.