Warping is not much fun. Warping is now on my list of responsibilities. At least I know I am accomplishing something critical to the operation of the telescope.

Exchanging segments does require some interesting procedures to realign each new segment, each must be warped and the edge sensors tuned. The first few hours of the night after a SegEx is used to evaluate the performance of the newly replaced segments. Using a special alignment camera system the optical figure of each segment can be evaluated and a set of corrections generated to be applied the next day… Warping.

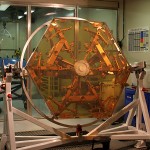

To apply the correct pressure there are small knobs and screws at specific points in the whiffle tree. Each adjustment point also contains a strain gauge, allowing the applied pressure to be measured precisely. A computer and analog interface allows all of the points to be read out and checked against the calculated values.

After setup, it takes about an hour to do each segment, an hour of painstaking frustration. the mirror cell is just the right height, too high to sit down and reach the knobs, too low to stand up fully. Working in a jungle gym of frigid steel just makes it worse. A day in the mirror cell is a nice recipe for a tired and sore body.

How careful was I? Did I get all of the points set correctly? The computer is displaying all of the correct numbers. I will not know until the next day, when the night’s performance data is reduced, when we can see the figure of the primary mirror and check the errors.

My first warp is a success, most of the segments show less than 20nm rms error. Next SegEx there are only two segments being exchanged, but Sergey is threatening to have two others re-warped to address some lingering issues. Four? Better than six. Only 360 adjustments to make, more or less.

Congratulations – you’re now an optician, or rather more precisely, a metrologist! Does it come with a raise in pay, or merely a more secure job? It’s nice when you get so valuable that they can’t get along without you… -Dean