I was looking at some photos and realizing how much perfboard I have used in recent years. I routinely find myself building small circuits, and that process almost always begins with grabbing a bit of perfboard from the supply stash.

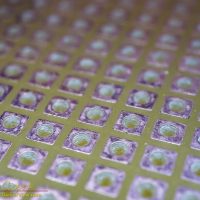

The holes are usually about 0.042″ and will accommodate a wide range of electronic components without modification. Cheap perfboard will have no copper pads or traces, good perfboard will have a pattern of copper traces and pads to which you can solder your components. Better yet is perfboard with plated-thru holes and pads on both sides.

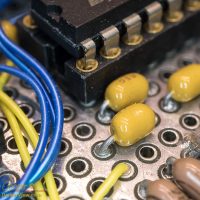

Using perfboard is easy, just thread the component leads through the holes, bend the leads over, and solder the connections. Many components feature 0.1″ spacing of the leads and naturally slip into the board.

I use enough that I keep a fair selection of perf on-hand. When buying a pile of stuff at the recent Radio Shack closing sale I bought a stack of perfboards. The boards can be a bit expensive, but at 80% off I grabbed all I could, at least of the sizes and types I like to use.

Layout out a circuit on perfboard is a bit of an artform. How to arrange and group your components to make connections easy and to provide a very functional circuit takes a good amount of forethought. A well arranged circuit minimises the number of wire jumpers you must use, making the connections with only the component leads.

A lot of through-hole leaded components remain available, and many surface mount parts can be soldered directly to perf. The common 0805 and 1206 surface mount resistors and capacitors solder neatly between holes, SOT-23 and DPACK transistors also solder to the 0.1″ spaced pads. It is only the high lead count IC’s that are a real issue, for those you need a breakout board. Indeed, there are a wide range of breakout boards available for many interesting and useful IC’s.

Despite fears of it’s demise, I will probably be building circuits on perfboard as long as I live. Yes, there is another circuit I need to construct this week, most likely a GenPIC PCB for control along with a bit of perfboard for some relays.

Hi Andrew,

Where did you get the perfboard in this pic:

http://darkerview.com/wordpress/wp-content/uploads/2017/06/CI58-34-17154-DC.jpg

I’ve been looking for perfboard with groundplane just like that.