The SBIG ST-i is a useful little camera, I have enjoyed using mine. I usually use the camera for autoguiding, but it can also be used for basic astrophotography and even some science. In preparation for using the ST-i with a group of students I had need to make a couple additional mounts. After I go to the effort of designing a simple solution to my problem I may as well share the solution.

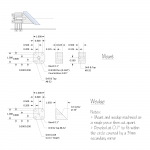

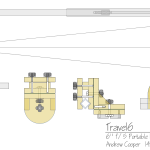

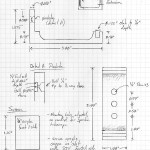

ST-i camera mount mechanical drawing

I have included the mechanical drawing for the mount in the link above. I machined this from a block of aluminum. There is no reason it could not be made of wood or plastic to allow fabrication with whatever equipment is available. For wood you may need to make the block a little longer and use inserts for the threading. Plastic could be done pretty much as drawn.

The version I made was milled from a solid chunk of aluminum, but a good version could be easily cut from wood and assembled with brass inserts. The design could also be 3D printed without much loss in mechanical robustness.

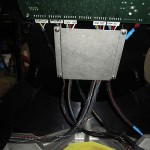

To mount a c-mount lens you will need the adapter ring sold by SBIG to convert the 1.25″ filter thread found on the camera to the 1″ c-mount thread. Still, at $40 this ring is a lot less than the $350 guiding kit. Good c-mount lenses can be found from many sources for less than $100. You will need a focal length between 75 and 150mm for a nice image scale and as wide an f/ratio as you can find. The kit includes a 100mm f/2.8 lens which I find is quite useful in guiding my Televue 76mm or the AT6RC.